written by: Tony Wai, President, SCMC Ltd.

Achieving the performance that Haidayuan can deliver today is not a one step process or a one-off initiative. Digital functions are for supporting business operations. Organization structure, direction, policies, systems and processes must be aligned and working in sync to take advantage of the technology. It took a long journey in internal evolution to come up to this high ground.

1. How it all started

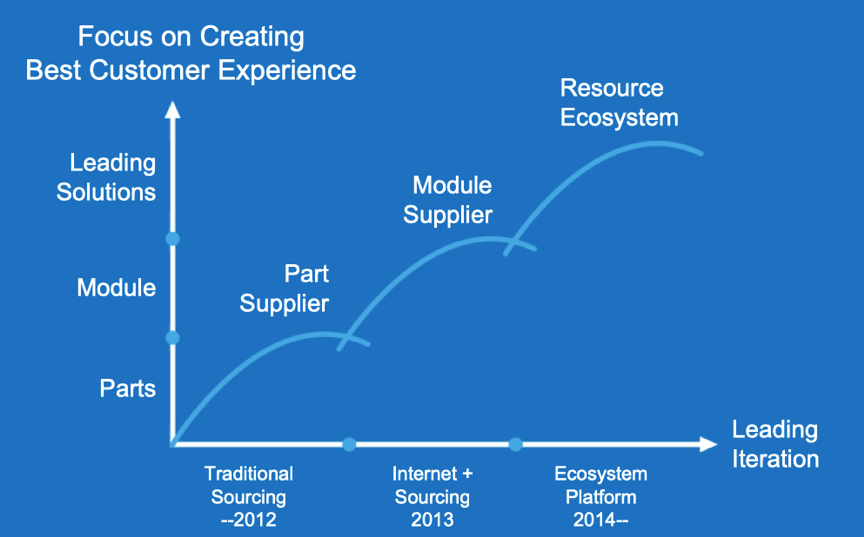

Haier Group was found in 1984 reformed from privatization of a small state-owned refrigerator factory that was in the verge of being broke. Over the history of its growth, the company had gone through strategic focus in 7-year period segments, from brand building, product diversification, internationalization to global branding. Today, the strategic focus is “network & platform”. These development cycles gradually transformed the company from a 19thcentury appliance factory to an open, entrepreneurial style platform-based company today. Procurement function evolved along the way in the process to accommodate the company’s strategy.

2. Centralization

The first wave of procurement restructuring dates back to the company’s diversification period after Haier acquired 18 companies, growing from a solo refrigerator business to a more diverse product portfolio including air conditioner, laundry washer, television and small appliances. Prior to 1999, Haier’s procurement organization was dispersed and spread out within subsidiaries, factories and plants of the 23 business units, with over 3000 suppliers. With the increase in acquired portfolio of companies, problems with decentralized purchasing became obvious: cost were high lacking coordination and volume leverage; quality were unstable without consistent and standard process; corruptions emerge with single point decision and lacking checks and balances.

As the company started to adopt ERP system in 1999, procurement activities was able to gradually switch to a more group-centralized model, integrating into a single “material logistics management” department. Sourcing for key direct materials was consolidated into 9 categories managed more professionally by a central commodity team. By 2002, supply base was rationalized and reduced by 72%. Scale-economy through volume leveraging resulted in 20% reduction in material acquisition cost; days of material inventory turn reduced by 67%, from 30 days to 10 days; and cash used for operation reduced by 73%. At the same time, overall purchasing and logistics personnel head count was reduced by 70%. First attempt for procurement transformation has led to successful start in the right direction. Yet despite the low-hanging fruit achievement, lacking systematic transparency, resistance to change and incomplete supply management process reform

3. Standardization

Haier procurement’s 2ndwave of change started in 2007 during the company’s internationalization period. To modernize management and bring operation up to par with international norm, Haier solicited consulting service from HP and IBM to help restructure the organization, redesign management process and implement SAP ERP system. Centralized procurement was reorganized into a “Global Operations” organization to support the companies international market expansion.

In the area of supply management, although centralizing procurement produced fruitful result, rapid international business expansion amplified some of the issues still not addressed, such as:

- Variation in commodity and category definition, leading to overlap and repeated parts

- Inconsistent policies and standards between business groups and product lines

- Backdoor selling

- Single point decisions in most area still lacks checks and balances

- Inconsistent quality and supplier qualification processes

Adding to that is the drastic increase of labor cost every year in the double-digit growth era of China pushed manufacturers to improve human resource efficiency and productivity.

Haier’s approach to meet this challenge was standardization.

Standardization would lead to higher efficiency while addressing the issues mentioned above, by reduce the numbers and complexity of parts and components, suppliers and processes, simply design, specification, decreased cycle time, lower maintenance costs and improve quality and consistency.

Standardization for material and process led to deployment of an important concept: modular design, an approach widely used and proven successful in personal computer manufacturing. The approach involves dividing a product into several major modules that may have more common usage across various products, with standardized interconnecting interface. The interchangeability of modules leads to broader utilization across the enterprise, allow an organization to deal with fewer suppliers, purchase in larger quantities, lower inventory cost and reduce production learning curve.

4. Modular Supply Strategy

The modules can be either manufactured in-house or purchased from suppliers. The analysis and justification of this make or buy decision would take into consideration of total cost factors, including manufacturing labor cost, internal vs. external expertise and efficiency, management cost reduction from reduced number of 1sttier suppliers, as well as innovation, technology, specialized components requirement. It had become obvious that modular design requires a radical procurement transition from parts and component base supply to solution-based module supply.

As can be imagined, this was not an easily cut over transition. It would demand major change in supply structure, and getting stakeholders involved to accept this new model of thinking.

Almost everyone in product ownership, design, manufacturing quality, supply management and all suppliers are an involved stakeholder for this change.

For Haier internally, this means a top-down approach to push for change with strong sponsorship from the chairman and CEO. Stakeholders in all product lines must be re-educated to take on the new approach. Modules and interface standards must be designed and defined with involvement and support from suppliers, and configuration information for modules must be developed to form a smart component database over time. Published interface standards would allow autonomous innovation and creativity by suppliers.

For suppliers, components supplied must be in predefined module form, complying to interface standards to ensure interoperability while maximized common usability, and optimized for serviceability, manufacturability, functions and quality. It would mandate that new supplier be solution-capable to start with. Incumbent suppliers must first go through a competitive process to bid for modular solutions to stay in the 1sttier supply business, otherwise they would be either downgraded to 2ndor 3rdtiers suppliers or abandoned by product owners.

The outsourced module supply strategy effectively raised the bar for suppliers and screened out suppliers that are not capable, leaving fewer and higher qualified (and most of the time larger) suppliers in the 1sttier. Less supplier would translate to more efficient management and better volume cost leverage.

Although the vision for module supply in appliance manufacturing is incredibly creative, this transition was painstaking and slow due to lack of systematic transparency, reference database and facilitation for interface standards, and a strong incentive for suppliers to convert. The conversion rate to module supply was roughly 49% until 2015, before a digital sourcing and facilitation platform is in place.

5. Mass-Customization with Leading Solution

As mobile technology becomes mainstream starting in 2012, consumers are sharing at the same time influenced by market information or product innovation in web speed from diverse sources, resulting in quickly-shifting personal preference. In its current “network and platform” strategy focused development period, Haier envisions that mass-customization is an approach to capture the benefit offered by big data in combination of IoT, where customized and fragmented market requirement can be met. This represents a major paradigm shift from the traditional mass-production model. Fortunately for supply management, this is also a digital age where technology can leverage.

Mass customization is a concept employed in the personal computer industry to quickly adapt to change in consumer demands with agility. To accommodate this, 1st tier suppliers must be able to respond quickly to demand change, both in design change and material supply in modules. To assure timely commitment to customers, 5 capabilities are considered critical:

- module solution design,

- quality assurance at module level,

- module delivery consistency,

- sub-tier supplier management

- financial strength for supply commitment

This requires their design methodology be agile, rather than the traditional waterfall process designed to a fixed-spec. Supplier must also move from a paper-based design to interactive design base on collaboration with customer. That requires highly professional capability with 3-D simulation and proof of concept online. They would also need to manage 2ndand 3rd tier suppliers for contracting, order release, quality, delivery and payment in synch with Haier’s dealing with the 1st tier module supplier itself.

To enable suppliers for mass-customization, a digital platform capable of facilitating 3 areas of transformation for supply management process and relationship strategy was considered necessary:

- from transactional buyer-seller relationship to a co-created value that shares interest in the relationship

- from parts and components purchasing to module solutions through user collaborations

- from internal evaluation to customer facing open user rating

This was the start point of Haidayuan.

The digital sourcing & collaboration platform was setup to support the transformations meeting 3 main objectives:

- frictionless entry for top class suppliers

- maximize stakeholder interest

- self-evolving dynamic optimization

The 5 critical supplier capability would later become the qualification requirements for suppliers to participate on Haidayuan.

The platform effectively accelerated module supply conversion rate by leveraging volume for higher incentive to winning-solution suppliers and highly visible competitive pressure for poor performance elimination, evolving into a resource ecosystem that drives common interest value from all parties.

6. Managing Paradigm-shift

With the implementation of Haidayuan, the job focus of Haier procurement professionals has gradually shifted from specific process handing to being a relationship facilitator and trusted advisor for both stakeholders and suppliers. Nevertheless, as can be imagined in a company in a traditional manufacturing-industry environment, Haier encountered challenges in its rough journey through the development of Haidayuan.

The first was overcoming a paradigm shift in existing work process for some stakeholders.

For example, the new process mandates a system of checks and balances transparency that separates potential supplier identification, costing and supplier selection, which could have been managed previously at a single point or entity. This caused issues or even “moved cheese” for some stakeholders. To overcome this obstacle, senior executive sponsorship as well as determined enforcement effort were necessary.

The new online design collaboration process was also new to product engineering. It used to just hand over requirement to sourcing. Now development team must change the mindset and perform an extra step — releasing preliminary requirements online — which they initially resisted. However, over time, they discovered that this step better supports development as it greatly enables design enhancement, leveraging from supplier expertise and obtaining first-hand information from supplier direction interaction. Gradually, this has become a feature they can’t live without.

The TQRDCB evaluation process was also was new to many parties involved, as it was only handled internally. It would take lots of training and experimenting to final convince all stakeholders see the benefit of take directly control for their input.

7. Digital Competency Development

In the process of developing Haidayuan, supply management function has evolved from a business-only player to a full fledge technology-integrated process owner, bridging the gap between functional expertise and technology application leverage.

Initially, Haidayuan’s functional requirements was drafted and issues were refined along as the development progress, with technical development work outsourced. After the first version of the system was released in 2015, Haier procurement realized that the software development service suppliers were not able to fully capture and align with the business needs timely. They made a 180-degree turn from the outsourcing strategy, building a small technical team, bring the project in-house, and continued software revision and core-function development.

This turned out to be the right strategy: It ultimately enabled Haier to adapt more quickly to change requirements while maintaining leading-edge and differentiating processes and practices core functions proprietary. In this process, the procurement and IT teams worked cohesively and effectively. Together they developed a competency that overlaps the two disciplines, jointly becoming experts in systematic and digitized business process that created additional innovations for Haidayuan.

As an example, the big-data dashboard initially developed for only executive decision-making support was expanded out of the original scope to adapt for module and supply life-cycle tracking. It was then further enhanced for automated-exception warning, monitoring and tracking. This extended the service of Haidayuan from module-based material level handling to the whole OEM/ODM process with information shared by suppliers. The feature was quickly rolled out and adapted by business units worldwide.

8. Tuning Performance Focus

Haidayuan’s performance optimization algorithm is also dynamically tuned from time to time to adjust for focus and resolve issues. For example, with an enterprise compensation structure that rewards immediately performance for the microenterprises, there was a tendency that most initiatives on Haidayuan requisition are more operational excellence (i.e., cost) focused, moving away from innovation-focus initiative as with the typical first round of requisition. Reward algorithm had to be adjusted so that a better balance of trade-offs between long term benefit (through technical leadership & innovation) and short-term benefit (through operational excellence and cost reduction) is achieved.

With over 3 years of development experience under supply management’s ownership of a digital platform, Haier’s team understands better than anyone that transformation is a perpetual process in an era of fast-reiterating disruptive technologies, and is prepare for the journey ahead.

- 还没有人评论,欢迎说说您的想法!